As a leading provider of warehouse location identification products and installation services, we are asked questions which are relevant to particular facilities, as well as those which are more common across the various sectors of storage and distribution. Here are some of those we can share with you.

If your rack or shelf locations cannot be reconfigured, or the location references are to remain the same for the duration of the facility, then yes lamination is worth having. Lamination adds to the durable nature of our rack labels, it helps protect the print and creates a thicker label which is less susceptible to damage. It does not protect against forklift or pallet impact though!

Yes, these are a common request from our customers looking for pick accuracy improvements.

In short, yes. Our teams are trained in-house and with the relevant external training centers to ensure they know how to do their job and how to do it safely. Any employee who we feel is endangering the safety of others is dealt with swiftly.

Yes, we supply all component items so customers can finish the signs themselves. It is rare we are asked but we appreciate that customers like to self-customize.

Yes, in small and large buildings. We are very experienced in working around other contractors on new builds and carefully plan with the customer and main contractors to achieve a completed installation.

Line widths are not critical, but there are several considerations to make, some are as follows:

Other considerations:

There are several things to consider with the height of signs, they are:

● Sprinkler interference –

Signs should always be placed at sufficient distance from sprinkler heads to ensure the diffusion is not altered or prevented by the signs or rails. If hanging the signs above, this is not an issue.

● Block stack storage height –

The signs will need to be higher than the highest stacking point, but you should consider here that if the signs are hanging behind the front edge of the stack, they will need to be higher still, due to the angle of sight.

● Scanner distance capabilities –

Most modern scanners are equipped with long range scanning components, however this should be checked with the manufacture/supplier. If you want to test the distance before ordering, you might consider requesting a sample to perform on site tests.

● Sign/barcode size –

In a simple explanation, the wider a barcode is, the greater the distance it can be scanned at. Having a wider barcode will need a bigger sign, resulting in a more expensive product.

Our teams are able to forecast, with a good level of accuracy, installation times of all products we produce and the floor markings we create. Many factors come into the calculation as you might expect, so a detailed discussion will be needed to develop the time frame. It will be this framework we use for our project planning.

Warehouse barcode signs are location signs equipped with long-range material used to print the barcode on. The material allows the user to stand around 49ft to 65ft away and scan the barcode with ease, if their hardware is equipped with the relevant components.

Lead times are variable, owing to quantity, complexity and production volumes at the time of order. We prefer to work swiftly with every order since we never know the scale or quantity of the next, so you can be assured that we will not delay the process once your order is placed. We do typically aim for a 1-2 week turnaround from order confirmation.

Depending on the scale and access requirements we may be able to working without effecting your operation, or we may need to provide detailed work plans which show how much we can do, where and when. The project team will also detail access requirements and safe working areas to be agreed and confirmed with the customer.

Yes, if we have a sample or measurements and a good image we can copy your label almost exactly.

Absolutely, we would be happy to do with this with any order.

We can create one from scratch if needed, there is a cost for this but we keep it low to ensure it is a cost effective alternative.

During an installation, our team on site can relay any updates or requests to the project team, or support you with ideas and possibilities. They are experienced with this situation and will work with you to achieve the preferred outcome. Our project and sales team will work remotely, on re-planning, pricing and scheduling to maintain a professional control.

After an installation, again just let us know. We can remove, cover up and install most products during an installation, and schedule for a return visit for amendments or additions.

Yes, driving straight over them is fine. Turning on them or scraping pallets across them are the worst things you can do.

It is essential to have a clean warehouse floor, particularly if you are operating a floor label system and have issues with floor marking durability issues. Labels can be cleaned, but will not withstand strong chemicals, which is why they are produced and priced to be a consumable item.

Aluminum framed labels would be a better product if your floor is dirty, but any label on a dirty floor will have dirt on it at some point. You many want to consider barcode hanging signs.

We have several options including mating, adhesive anti-slip products bolt down anti-slip plates as well as anti-slip paint coatings. All are designed for specific uses and varying durability but ultimately, consideration must be given to the use of an area where injury is a risk.

You can find some of the standard products on our anti slip floor tape page.

Yes, simply because the raw materials we need to create color labels are more expensive, however once an order is over a certain size, the extra cost becomes negligible.

There is always a best fit design, but a best fit for your facility is key to making your operation efficient, but not necessarily the same for another.

We are able to recommend ideas from previous designs, from knowledge and experience in the industry, as well as samples for you to test. Most customers have an idea of what they want or need, if we think there can be improvements or something has been overlooked, we’ll let you know and discuss the details.

It depends on several things, the cleanliness of the surface, the surface texture and temperature.

The surface must be free from dust and dirt, oils, cleaning solutions and moisture and any coatings which are loose.

The surface texture is important, for example standard adhesives will not stick to an unfinished wood surface or a galvanized surface where microscopic elements prevent the adhesive working. Additionally, a surface which is very uneven, like a rough plastic mold finish, does not provide enough flat surface area for the adhesive to bond.

Finally, temperature can affect the adhesive. In very cold environments, including chillers and freezers, the elements of the adhesive begin to freeze. Fortunately they do not neutralize, so once warmed they can be used.

Yes, let us have the location reference(s) and we’ll get them out to you as quickly as possible.

Almost any color can be supplied in board and character material. Customers looking to match company brand colors or a previous scheme can be accommodated with a huge range of color options to choose from.

For those looking for more intricate designs or information and diagram signs, colors are unlimited. We utilize digital print technologies for these which are almost limitless.

OSHA recommends the following:

Most work carried out by ASG Services is done with yellow and/or white. Occasionally we will be asked to use red, green, blue and grey. If in doubt ask what we can provide, almost any color is available.

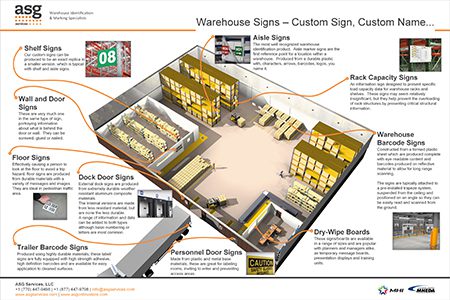

The options are endless, so it really comes down to the information you want or need to provide. Also the space available, your budget and how easy you want to make location identification for your team all play an important part.

To save time reading 2000 words on label design call us on (877) 447-9798, to discuss your situation. We can recommend a best solution and fit for your needs.

Visit our warehouse labeling pages for more information or our online store where you can purchase online.

We are not a graphic design studio but we are capable of designing any label layout required. Variable content data and multi field options are possible, our only restriction on the number of barcodes and characters is the size of label you request. We will always suggest a size which best suits your requirements.

Quantities, sizes, location, aisle widths, beam heights, building operation status, start date and a thorough conversation so we understand exactly what you are hoping to receive from us and to achieve from using a company like ASG Services.

This is potentially a long answer, however to make things a little more simple… We ask for a list of location references or sign data to be provided, ideally on an excel spreadsheet. In addition, we would ask for any drawings or design ideas you have, based on the quotation you received.

If you change your design idea and need a new quote just ask, it’s better to ask before we start production.

As well as the information to create your signs, we’ll also need payment and/or invoicing details, a delivery address or site address for a warehouse sign installation.

Embedded floor labels are the most durable we can provide. Embedded labels are less likely to become damaged as they are below the surface of the floor, so they are driven onto and into the side of, so they are also less likely to be ripped off through impact.

Embedded labels are not a cheap options, and must be cleaned regularly, but they can withstand steel stillages being dragged across them, which is the most damaging action we could test against.

Other options include floor label frames and floor label protectors and where possible, we strongly recommend warehouse hanging signs. All are available from our online store, or if your project is large, contact us for quantity based pricing and installation if needed.

Order quantities are irrelevant at ASG, we treat all orders as a customized requirement. We do have a minimum order value in dollars, but this is nearly always irrelevant.

Preparation helps improve durability, so if you are operating a very busy facility or moving items which are heavy, you will likely need a preparation method.

There are several options to consider:

It is typically more cost effective to have a preparation method when compared to several years of recoating and touch ups which will be needed.

Any size you need. Every order we fulfill is customized, so you can specify a size, and we will provide the product as needed.

All products from ASG Services are custom made. We can supply any size, color and content required. Our online store lists stock sizes, for those looking to purchase basic items.

You will find that recoating is only needed where lines are driven over or turned on. Floor markings along the length of bulk storage lanes for example, typically remain as good as when they were installed.

Striping applied directly to the floor in busy areas may need a recoat within the first month or two in heavy traffic areas or more typically the first year of use. Shot blast prepared lines should reach 3 to 5 years and diamond shaved around 5 to 6 years.

These are estimates and very based on facility use, traffic levels and floor conditions.

The barcode you choose to use is dependent on your location or product reference data requirements.

Although we are able to produce almost any barcode type you require, Code 128 is by far the most requested by the storage and logistics industry. This is impart due to the range of characters which can be used (128), being all digits, characters and punctuation and because of its data to size percentage, lots of data can be stored in this narrow width barcode.

Code 39 is the next most popular, which is less useful in terms of characters it can encode, but it is great for its simplicity and ease of scanning capabilities. This is often used with operations handling product specific references and a need to work quickly.

More recently we have been asked for DataMatrix and QR Codes which can contain huge amounts of data compared to linear barcodes.

We produce self adhesive floor labels which are of a durable grade for use on warehouse floors, and we have combined these composite labels with special low temperature adhesive, which work in extremely low temperatures. They are ideal of use in cold store facilities and freezer chambers. We recommend you thoroughly clean the floor surface prior to application and only take the labels into the freezer once you are ready to apply them for maximum performance.

Our high performance freezer adhesive is suitable for application at -65ºF or -54ºC.

Contact us and request samples.

Put simply, polyester and polyester composite label material is more durable which prevents barcode distortion during application and shrinkage over time. It also makes it much easier to remove the label, from time to time you may want to re-label your locations due to configuration changes or WMS changes, polyester and poly-composites can be removed without tearing, unlike vinyl materials.

Combining your storage markings with passageways or safety markings can help save money over time. This comes from shared demarcation boundaries and downtime during installations, plus reduced mobilization, plant hire and material costs.

The simple and short answer is durability. Durable line striping is more expensive because there is a lot more work involved in preparation and the machinery needed.

Preparation is critical for paint to adhere well to most surfaces and unfortunately, concrete is a very hard material which takes time to work and prepare. The positive consideration is that more durability means less re-working later, so the investment pays off.

It is true that location labels do not need color to work, but we recommend color to help the users identify key location information quicker. Color is know to improve speed of identification, to read more visit our warehouse color coding article.

Color identification may be used as a level indicator on racking where each level in a rack bay has a unique color, so as the operative looks up, they can distinguish the level quickly and shorten their reading time. It can also be used as a zone identifier particularly with bulk storage floor locations, aisle groups in racking and shelving is another.

Another well represented use of color is with warehouse striping for staging lanes, bulk storage bays and walkways. See our warehouse striping page for more information.

Some customers use it for aesthetics for their in-house branding.

For the most accurate price and planning, it is best to give us as much as possible, having a drawing helps you visualize and us to plan and quote. CAD are easiest as we can use them to pull measurements from, while PDF with measurements added is another great way to provide us with the information.

However this is not essential, we can help with basic depictions or arrange for a partner firm to visit site and create a much more detailed drawing, contact us for pricing.

Yes, floor labels are the most susceptible ID label in the warehouse, but they are tough and if used correctly can be extremely cost effective.

We advise users to place the label to the left or right of a location entrance to help avoid continual impact, and where possible, that pallets and forks are lifted clear and that truck wheels are not turned while the wheel is on the label.

You can drive over our labels all day, but like aluminum, frames and steel plates, if they are impacted unduly, they will fail.

Yes, we can retrieve information from our archive and apply this to your new location references, effectively replicating your previous warehouse identification system.

Yes, we operate an archive system so your previous orders including designs, location references and other documentation will be available for retrieval.

Most of our installation projects are US based, but we also travel throughout the world with customers who know and trust in our services. We also partner with similar suppliers around the world, so we can often refer you to a company closer to you if needed.

The most common dimensions are in walkway widths (4ft), pallet lane widths (pallet type dependent plus the line width) and line widths (4”), but every facility is different and may need custom sizes.

OSHA provide the following:

“The lines used to delineate the aisles may be any color so long as they clearly define the area considered as aisle space. The lines may be composed of dots, square, strip or continuous, but they too must define the aisle area.

The recommended width of aisle markings varies from 2 inches to 6 inches; therefore, any width 2 inches or more is considered acceptable.

The recommended width of aisles is at least 3 feet wider than the largest equipment to be utilized, or a minimum of 4 feet.”

Standard Number: 1910.22(b) – Compliance with Aisle Markings (Part 1910.22(b)) – [Corrected April 17, 2009] – https://www.osha.gov/laws-regs/standardinterpretations/1972-05-15

Yes, this is a specialty of ASG Services. Working in and around a fully operational distribution center can be daunting, not to mention it having a significant impact on productivity. Our teams are very experienced in how to work within these facilities and appreciate that the customers work ultimately comes first.

There are many ways, depending on the use, your facility infrastructure and building design as well as sign material allowance. It would be easier to discuss you exact situation with our team, so please feel free to contact us.

Keeping the floor area clean and clear of debris is the easiest thing any facility can work on, however we strongly recommend customer work on their training programs to encourage the following:

Floor labels become screwed up when MHE wheels are turned while on the label. The adhesive and materials are tough, but the twist pressure is extreme. Consider placing them to the side of a storage lane, or placing markers on the floor for drivers to hit before turning their wheels.

Warehouse shadow boards can be heavy, and being used in industrial facilities means they need to be secured well during installation. Hardware capable of holding 100lbs is necessary and so tooling and capability is not considered straight forward. A good in-house facilities team will be more than capable, however if they are always busy or if you do not have one, employing installation services is advised.

Our teams have provided these services many times as part of our wider warehouse identification and marking projects. Being onsite with equipment and manpower makes it cost effective and professional.

General use tools and cleaning implements used in industry are notoriously less respected than those owned by employees. It is therefore not uncommon for them to be left in poor condition, where they were last used. Facilities operating 5S methodology and utilizing shadow boards drastically reduce tool waste by placing responsibility on those taking items. Furthermore, activities can be introduced which prevent a process from being complete until all items are replaced.

Items used and returned tend to be in good condition, instead of being left where they were last used and in a damaged condition. This is because each has their designated place and poor condition is quickly seen.

If you are not able to generate a location file from your warehouse management system, we recommend you use a spreadsheet to help build your own. Spreadsheets allow you to use columns to separate the location sub references, and the rows to quickly expand the number of derivates per run. These columns of data can then be combined to create the barcode data and separately to create the readable elements with separators so operatives can read the rack and shelf location names easily.

Read more on how to build a warehouse location data file.

If we first list the five steps, Sort (Seiri), Set (Seiton), Shine (Seiso), Standardize (Seiketsu) and Sustain (Shitsuke), you can quickly appreciate that a shadow board ticks all the boxes.

Sort: The boards provide the system to ensure all items are located in the correct place.

Shine: As well as the tools themselves potentially being used for cleaning, all tools returned are more likely to be cared for and returned in good order.

Standardize: Uniform tooling for specific activities means the user always has the best implement for the job in hand.

Sustain: Having a central point of resource improves efficiency, reduces downtime, increases productivity and a sense of achievement, which ultimately helps retain your valuable workforce.

Shadow boards are a form of storage devise. They are designed to hold and present implements in a way to show where each goes. Items such as tools in manufacturing, and cleaning items, are the most common seen in industry.

The items clip-in, hook-on and in some cases, sit against the boards, in designated places. Their position is determined in design with the silhouettes added to display clearly where each item goes.

These are storage panels, designed to hold and display tools, cleaning implements, etc. A user can quickly select, use, and replace each item needed, which is represented by a ‘shadow’ of its unique size and model for quick visual reference. Shadow boards come in all sizes depending on item size and number to be stored and are most often used in industry.

In some industries, the process isn’t complete until all items are returned, for safety reasons. In others, they help improve organization and efficiency by keeping equipment in their storage place.

Knowing where the equipment is to clear debris, helps reduce down time. Also, knowing that all tools are returned, confirms that a wrench was not left in a critical area of an aircraft after maintenance checks.

Every industry which uses a form of tool can benefit from shadow boards. Regardless of the tool size, quantity or use, anyone looking for the tool, or replacing one will know exactly where to go. In addition, anyone will be able to see the item missing and what to look for to make the cleaning station or assembly tooling complete.

The primary component of a shadow board is the graphic display, which can be applied to any sign material and then mounted. However, their nature and use, require them to be mounted to a stable structure so the tool holders can be attached securely.

Our approach is to recommend a premium medium density overlay (MDO) board. The reason for this is, we can apply the image directly to the board, assemble the board with holders and implements and ship them complete, so all the customer needs do is mount them to the wall, against racking or into a frame.

Shadow boards are used by people, so positioning them in or by a work area is obvious. However, those areas can be enormous in distribution centers, so a more strategic approach is needed. For example, one isn’t needed at the end of every rack aisle, but every fifth or tenth might be necessary, and at both ends. They need to be in a safe area for people to use them, alongside a walkway for example, not on a forklift truck route. And of course, near high traffic hot spots where impacts or accidents may occur.

Yes. Floor labels are the most susceptible location label in a warehouse, they are tough and if used correctly can be extremely cost effective, but they are impacted by material handling equipment, pallets, cages, skids, and everything else which is in contact with your floor.

Ways to avoid damage include:

You can drive over our adhesive floor labels without damage being caused, but anything impacted will be damaged, even the protective covers and frames. Consider a training session with your MHE operators also.

They are ‘digits’ to be double ‘checked’ against the warehouse management system (WMS) records. Once the operative has arrived at the pallet or shelf location, they are asked by the system to provide the ‘check-digit’ information which ensures it matches that on the pick sheet or terminal. If their is a match, it is further confirmation they have found the correct location or product and they are able to proceed with the item pick. If it is a failed match, the operative is prevented from completing the pick task, and so knows to look again for the correct storage location.

Check digits are often provided by the warehouse management system, as randomized characters forming an addition to the location code. Most barcodes include a check digit within the symbology, calculated by other characters which form that barcode. In a storage environment, the check digit is typically a separate feature.

Below, you can see the user check digit presented as characters with a black background on a warehouse rack label and a barcode location sign. The operator reads the location reference, scans the barcode and enters the check digit.

If the floor is a regular smooth concrete surface and clean, you will not need to grind.

A thorough clean is recommended, and a solvent clean would be advisable if you suspect any contamination. Once the floor is dry, it should be good to go.

If the floor is rough, then you would need to make it smooth. Either by grinding, or coating with a screed.

Mighty Line floor tape is very strong, so with scrapers and elbow grease, you will be able to remove it in one piece. There may be residual adhesive left in places, and a simple adhesive removal spray would take care of that.

If you still have questions which need answering now, call us on (877) 447-9798.

You can ask and send more with an email, so send us all you can and we'll give you the best response possible.

Our online store provides customers with the opportunity to purchase standardized products. The same technology, production and quality control methods are used, so you can be assured of their performance and durability.

Browse now