The decision to use either is not difficult, how to use them is key. ASG Services project teams work alongside barrier manufacturers and distributors with combined installations and have described below, how you might consider your needs.

Warehouse barriers provide physical safety protection in areas of danger and against moving objects. Material handling equipment (MHE) of all sizes present a danger, small, large, powered or pulled. Typically, barriers are used in warehouses to prevent MHE from impact with racks, building structures and columns or to prevent them driving off loading ramps, or into other larger vehicles such as semi-trailer trucks. This group of barriers might be referred to as traffic barriers.

Pedestrian barriers are often similar but higher in design, preventing people entering danger areas, or falling into the path of danger and vehicles. Where vehicle strikes are less likely, they would be referred to as pedestrian guardrails.

The most common uses in distribution centers are rack protectors, pedestrian guardrails, traffic barriers, height clearance bars and bollard posts. Manufacturers design for direct impact, however deflection is the most common impact type in the workplace, most notable where marks are left on the barrier.

Barriers are more suitable than line striping where total protection is essential, or containment is needed. Pedestrians walking alongside walls, is an example where people need protection from being crushed. The same impact in an open space is more likely to see the pedestrian pushed clear. Containment would be where a vehicle is driving down a ramp and will be contained preventing it driving off the side.

Stationary equipment can be protected with barriers or guardrails, but the most effective method is fencing. Partition fencing is mostly seen in manufacturing environments, but in warehouses where lots of people are moving quickly, fencing is a better option for stopping people. It is also more visible due to its size, and by default is avoided by drivers.

You could categorize and prioritize your facility needs under the following headings, before contacting a barrier supplier:

When thinking about installing barriers remember, a barrier is only as good as it was installed. A barrier, guardrail or fencing will fail instantly, if it is not fitted correctly.

Knowing the best method and anchor hardware is critical. We would highly recommend using an experienced team who have the right tools, materials and understanding. Every detail, even down to the torque settings for the anchor hardware is important. Manufacturers and distributors will often have this resource and when you receive their price, don’t compare it with a cheap handy man, compare it to the potential cost of an accident in your business.

While barriers provide a larger physical presence, there are situations where floor striping is the best choice or only option, to maintain a productive operation.

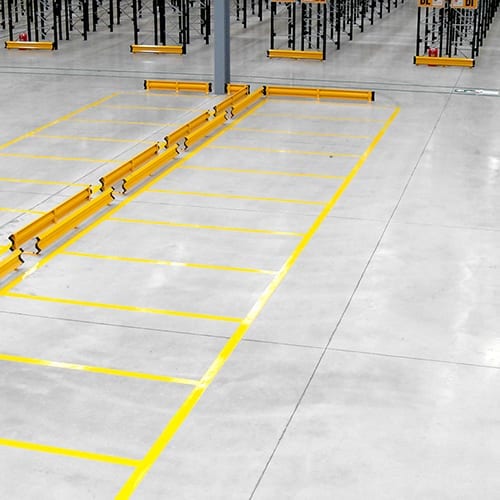

Floor striping is used primarily when aisles or passageways need to be marked for organized storage and personnel safety. Deciding on the optimum layout and designs is important so it portrays a clear message as well as guidance. Simple is best for speed of recognition and color can be used to improve this further. Read more here about Color Coding in Warehouses. Walkways could be green with a zebra crossing where they cross vehicle transit routes, storage lanes could be yellow to help guide storage locations and red hatched areas could be restricted zones for stopping or storing.

Warehouse striping installations vary in cost, based on the method of concrete preparation and paint system to be used. Typically, the lower durability options are quicker to apply and so cheaper, the more durable methods are therefore considered an investment. ASG Services work with customers to create a mix of solutions. They ensure the most durable method is used where it’s needed and less durable methods where traffic is minimal. This helps maximize budget, performance and investment as well as the impact on operations during installation.

Clearly marking boundaries, aisles and areas of travel for vehicles and staff members should be a priority to avoiding impacts. It’s often essential when a barrier would stop either functioning. Therefore, it is even more important to use a durable and highly visible method, instead of the quick fix.

If you’re thinking of defining space inside your warehouse, the combination of barriers and floor striping should be a the most obvious solutions considered.

Most facilities require both to keep vehicles and pedestrians separate. If possible and where the pedestrian is between the vehicle and a structure, then choose a barrier. If there is limited space for a barrier, consider an alternative route for the pedestrian or vehicle. If there is no other than both using the space, then choose line striping. Also consider safety signs to present messages or proximity sensors with light and sound, to further heighten awareness.

Where a pedestrian route continues beyond the safety of a barriered passageway and across the path of MHE routes, there is little option other than to use line striping. To increase awareness in this situation, consider zebra crossings and high contrasting colors on the floor, as well as on surrounding barriers. This will intensify the presence of danger by all in the area. Furthermore, you could use pedestrian gates on barriers to stop people walking straight out. This will help make them more aware and give drivers time to spot and react to pedestrians entering their workspace. Proximity sensors with lights can also alert drivers and may be more relevant to use vehicle gates where pedestrian flow is far greater than vehicles.

Choosing the right line striping design is down to you. ASG Services can help with ideas from their experience, but ultimately, it’s how the markings best work for you and would be best understood by your employees. You are the best person to answer that. Barriers on the other hand can be, and in most cases should be, recommend by the manufacturer. Once you’ve decided where you want them to be placed, they will tell you the most appropriate design configuration. ASG Services does not work with any barrier manufacturer exclusively but agree that cheap is not always the best use of your money.

To find out more about warehouse line striping, read ASG Services document called Internal Line Striping. Once you’ve determined the layout needed, this will guide you to making the most informed decision possible.

Send an email for answers to questions or more information on where ASG Services can provide help, recommendations and services.

We're here all day everyday, call on +1 (877) 447-9798 and we'll do our best to help.

We don't just customize, we have a store where you can buy items online too.

Epoxy Floor Striping

Epoxy Floor Striping

Unprepared floor striping is a term given to epoxy paint which is applied to the floor without any concrete preparation taking place.

Shot Blast Floor Striping

Shot Blast Floor Striping

The preparation method used, of removing the concrete surface using a shot blast machine, combined with an epoxy resin compound or similar applied, is the most cost effective high performing solution available.

Durable Striping

Durable Striping

The premium warehouse striping solution is ASG Services world renowned embedded striping.

Floor Tape

Floor Tape

Adhesive floor striping tape is easy to install, clean to use and can be applied quickly if needed. ASG Services provide several options to suit durability and budget needs.

Floor Coatings

Floor Coatings

Throughout the warehouse and distribution industry, ASG Services have provided floor coatings for new and existing facilities.

Our online store provides customers with the opportunity to purchase standardized products. The same technology, production and quality control methods are used, so you can be assured of their performance and durability.

Browse now