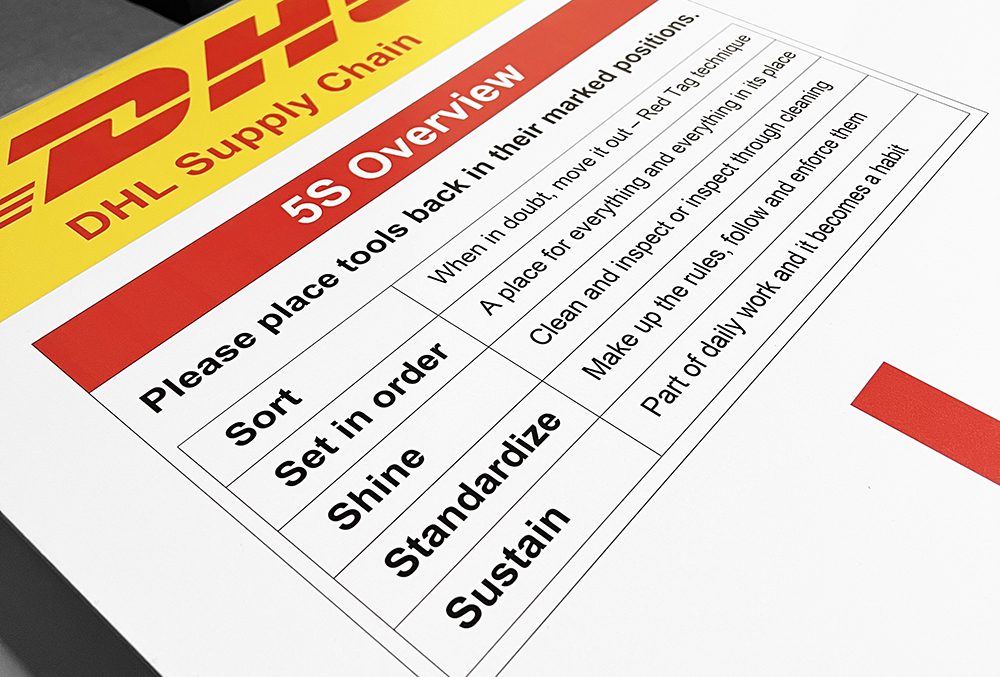

Workplace custom shadow boards are a familiar organization tool, made popular as safety, efficiency and accountability become a critical factor of any business. Their place in the logistics and distribution industry are obvious where a need for space, time and movement optimization, results in profit.

ASG Services shadow boards are a combination of custom design, durable materials and high quality components, setting new standards in performance and convenience with flat pack or assembled options, as well as installation services for larger projects. Working with 5S principles, designs are user friendly and specific to the customers needs.

Understanding the sourcing issues of durable shadow boards, quality implements and labor to construct the boards, ASG have ben utilized by many market leaders to provide a turn key product and service, providing every item needed, as well as installation services on larger projects.

Our design teams work with you and the tools you select so facility needs, corporate image and messaging are met.

Unique components can be accommodated, whether you’re in warehousing, aerospace, manufacturing, pharmaceuticals or something else, we can create shadows for your specialist tool. This approach allows our customers to achieve their ideal shadow board configuration.

As trusted suppliers to many worldwide brands, we are experienced in handling brand identity and provide full consultation, design and proofing before any production begins.

| Medium density overlay (MDO) board is ideal for busier facilities which need a unit to withstand the rigors of a fast paced environment. |  |

| Thick panel PVC board is another great option giving added resilience in damp ambient conditions. At 1-2” thick, it’s an excellent cost effective alternative to MDO. |  |

| Aluminum composite material (ACM), is recommended for external use. The 1/8” thick material construction can withstand all weather and climate conditions, so if you need snow shovels, ice scrapers or a stiff broom for outside, they could have their place. |  |

ASG Services is the leading provider of fully managed installation services, our teams are employed by ASG Services, fully trained and insured to work on any customer site throughout the US and beyond.

Their work on projects has created the expertise and experience needed to apply attention to detail and accuracy needed for complete and successful installations every time.

Working with small and large companies for many years enables use to plan every project, but also adapt at speed during the process, much faster and more efficiently than others in the industry. You can read more about this on our sign installation page.

These are storage panels, designed to hold and display tools, cleaning implements, etc. A user can quickly select, use, and replace each item needed, which is represented by a ‘shadow’ of its unique size and model for quick visual reference. Shadow boards come in all sizes depending on item size and number to be stored and are most often used in industry.

Warehouse shadow boards can be heavy, and being used in industrial facilities means they need to be secured well during installation. Hardware capable of holding 100lbs is necessary and so tooling and capability is not considered straight forward. A good in-house facilities team will be more than capable, however if they are always busy or if you do not have one, employing installation services is advised.

Our teams have provided these services many times as part of our wider warehouse identification and marking projects. Being onsite with equipment and manpower makes it cost effective and professional.

General use tools and cleaning implements used in industry are notoriously less respected than those owned by employees. It is therefore not uncommon for them to be left in poor condition, where they were last used. Facilities operating 5S methodology and utilizing shadow boards drastically reduce tool waste by placing responsibility on those taking items. Furthermore, activities can be introduced which prevent a process from being complete until all items are replaced.

Items used and returned tend to be in good condition, instead of being left where they were last used and in a damaged condition. This is because each has their designated place and poor condition is quickly seen.

If we first list the five steps, Sort (Seiri), Set (Seiton), Shine (Seiso), Standardize (Seiketsu) and Sustain (Shitsuke), you can quickly appreciate that a shadow board ticks all the boxes.

Sort: The boards provide the system to ensure all items are located in the correct place.

Shine: As well as the tools themselves potentially being used for cleaning, all tools returned are more likely to be cared for and returned in good order.

Standardize: Uniform tooling for specific activities means the user always has the best implement for the job in hand.

Sustain: Having a central point of resource improves efficiency, reduces downtime, increases productivity and a sense of achievement, which ultimately helps retain your valuable workforce.

Shadow boards are a form of storage devise. They are designed to hold and present implements in a way to show where each goes. Items such as tools in manufacturing, and cleaning items, are the most common seen in industry.

The items clip-in, hook-on and in some cases, sit against the boards, in designated places. Their position is determined in design with the silhouettes added to display clearly where each item goes.

In some industries, the process isn’t complete until all items are returned, for safety reasons. In others, they help improve organization and efficiency by keeping equipment in their storage place.

Knowing where the equipment is to clear debris, helps reduce down time. Also, knowing that all tools are returned, confirms that a wrench was not left in a critical area of an aircraft after maintenance checks.

The primary component of a shadow board is the graphic display, which can be applied to any sign material and then mounted. However, their nature and use, require them to be mounted to a stable structure so the tool holders can be attached securely.

Our approach is to recommend a premium medium density overlay (MDO) board. The reason for this is, we can apply the image directly to the board, assemble the board with holders and implements and ship them complete, so all the customer needs do is mount them to the wall, against racking or into a frame.

Every industry which uses a form of tool can benefit from shadow boards. Regardless of the tool size, quantity or use, anyone looking for the tool, or replacing one will know exactly where to go. In addition, anyone will be able to see the item missing and what to look for to make the cleaning station or assembly tooling complete.

Shadow boards are used by people, so positioning them in or by a work area is obvious. However, those areas can be enormous in distribution centers, so a more strategic approach is needed. For example, one isn’t needed at the end of every rack aisle, but every fifth or tenth might be necessary, and at both ends. They need to be in a safe area for people to use them, alongside a walkway for example, not on a forklift truck route. And of course, near high traffic hot spots where impacts or accidents may occur.

If you have questions about customizing shadow boards for your needs, please call on (877) 447-9798, we are happy to help.

Send all the questions, details, pictures and drawings you have and we'll get the best information and response to you as soon as possible.

Our online store provides customers with the opportunity to purchase standardized products. The same technology, production and quality control methods are used, so you can be assured of their performance and durability.

Browse now