Adhesive floor striping tape is the cost effective, non-permanent alternative to floor paint. We provide a range of floor tapes, each with its own characteristic to optimize budgets and benefits for our customers. Options in durability, texture and adhesive capabilities help meet a wide range of application and use requirements.

ASG Services partner with the Mighty Line® brand for their quality, supply and reliability and unmatched product support. They have extremely durable floor tapes specifically developed for use in busy distribution center environments and are proven in affordable high performance.

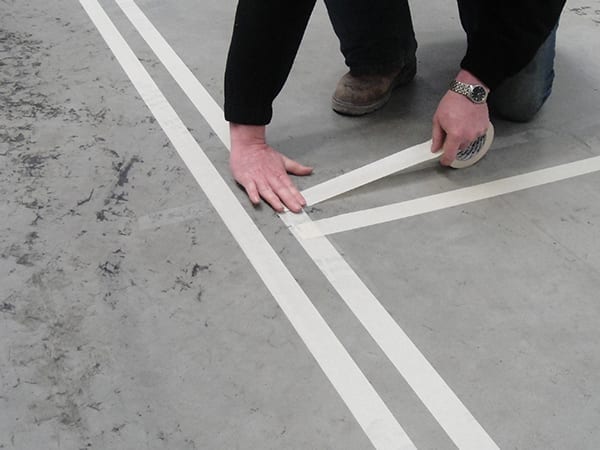

As well as selling floor tape, ASG Services bring their unique project managed installation services. Our experience of new build and live operation installations helps us swiftly complete work, but more importantly the preparation and level of accuracy of our team’s work, far surpasses that of general contractors.

Using floor striping tape does have some in-use drawbacks, which we highlight to ensure that tape is the right option. We aim to avoid unrealistic expectations, regardless of how well floor tape can work.

Anti-slip striping tape has many functions all with the common need, to create floor markings with added grip. This is often essential in and around storage facilities and distribution centers where pedestrian walkways and striping come close to doorways which are susceptible to moisture. Anti slip striping tape is also excellent when used on steps, creating improved surface grip and high visibility markings for stair nosing’s.

PVC tape is the cheapest option in ASG Services floor striping tape range, it is thin, available in a range of colors and available from most hardware outlets. ASG Services sell this item in their online store, however it is not a product recommended in our projects due to its lack of durability and general poor performance.

The durability of floor striping tape should be a priority consideration. In most cases, floor tape is an ideal solution with fantastic benefits, particularly in reconfiguration scenarios and low to medium traffic areas. However, we strongly advise you to contact us about your plans if you are unsure. We can recommend the best tape for your needs, or an alternative striping solution.

Pre-installation preparation is essential. All surfaces should be thoroughly cleaned of dirt, dust and residue for the best adhesion and performance. Failure to do this will result in the tape peeling, if it sticks at all, and to prevent cracking, shrinkage and bubbling.

There are various tools available to help with the installation of floor tape. Some low cost options will help you apply the tape, but with a less accurate finish. More costly variations perform much better. Our installation teams have tried many and speak well of them but have techniques that enable them to apply it more accurately and in greater quantities.

ASG Services’ fully managed installation teams operate throughout the US, the striping teams are trained in all aspects and insured to work in all customer facilities. Their experience in new and operational buildings means they can follow sequenced schedules or adapt quickly where customer needs are prioritized.

Thanks to their knowledge in correct application processes, the results are impressive and always end as a successful floor tape installation.

Read more about our striping installation services, and read more here about the striping installation projects we’ve provided.

If the floor is a regular smooth concrete surface and clean, you will not need to grind.

A thorough clean is recommended, and a solvent clean would be advisable if you suspect any contamination. Once the floor is dry, it should be good to go.

If the floor is rough, then you would need to make it smooth. Either by grinding, or coating with a screed.

Mighty Line floor tape is very strong, so with scrapers and elbow grease, you will be able to remove it in one piece. There may be residual adhesive left in places, and a simple adhesive removal spray would take care of that.

In short, yes. Our teams are trained in-house and with the relevant external training centers to ensure they know how to do their job and how to do it safely. Any employee who we feel is endangering the safety of others is dealt with swiftly.

Yes, in small and large buildings. We are very experienced in working around other contractors on new builds and carefully plan with the customer and main contractors to achieve a completed installation.

Line widths are not critical, but there are several considerations to make, some are as follows:

Other considerations:

Our project teams are able to forecast, with a good level of accuracy, installation times of all products we produce and the floor markings we create.

Many factors come into the calculation as you might expect, such as quantities, dimensions, etc, so a detailed discussion will be needed to develop the time frame. We use this framework for all our project planning as we know our speedy completion is often the last in the larger process.

Call us today and get the answers you need before buy floor tape, (877) 447-9798.

You can send your questions along with images and drawings so we can help you with your project in more detail.

If you're happy to buy it right now, visit our online store and we'll get it on its way to you.

Our online store provides customers with the opportunity to purchase standardized products. The same technology, production and quality control methods are used, so you can be assured of their performance and durability.

Browse now