Multi-level warehouse rack labels are designed to contain and present information for several locations, usually in the vertical stack, and there are several names for them, examples are:

The labels are typically placed on the rack beam face or frame post upright.

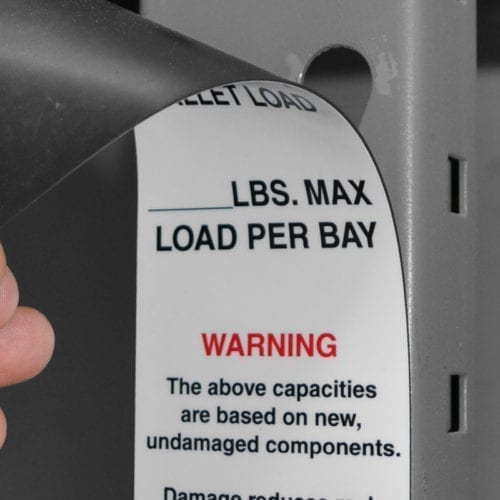

Durability is often an issue with the label placed on rack frames. There seems to be a desire among warehouse operatives, to make holes in the labels which destroy barcodes. Some have moved to placing a label on a panel of plastic or metal, which is bolted, or cable tied to the frame. As well as being expensive in materials, this is also costly in installation labor. It’s also not particularly durable, easily broken and can cause a snag point leading to damaged frames.

ASG Services overcame these issues a long time ago with their plastic composite label. A puncture proof, none-tear product with a high strength adhesive backing, they are very cost effective in comparison, very quick to install and offer high definition printed barcodes for rapid scan results. Request a sample, you will be pleased.

Several adhesives are available to suit the environment, including one which can be applied at -22˚f which has been extremely popular with the food and beverage industries. It is suitable for cold stores and freezers.

View more of our rack labels here.

Multi-level rack labels have become more popular in recent years for several reasons.

Two categories of multi-level rack labels exist. Vertical and horizontal. Each have their own characteristics and can be produced with linear barcodes, 2D and linear barcodes in a diagonal configuration.

Vertical designs are given various names. Totem, tree, upright, frame, man down and vertical post labels, are all self-explanatory given the layout of information and appearance of the label. The layout follows an obvious convention of lowest at the bottom and highest at the top and ordered accordingly in between. Color is a great addition to help differentiate levels which helps reduce mis-scans.

A horizontal alternative is sometimes called a step, man down or multi-level beam label. Layouts typically run from left to right with the lowest level on the left and can also be designed with the choice of barcode type, color separation, arrows and even images.

Images tend to be an option used by manufacturers in their component storage cribs. The most recent introduction, coming by way of automation in logistics, is a horizontal multi-level shelf label. These are used on mobile shelf systems which are transported by robots to pick stations. Automation still needs identification where people are involved.

Customizing warehouse rack labels is what ASG does. We make multi-level rack labels in configurations that suit the customer, not how we prefer to make them, and we provide a host of peripheral services that others charge for. We are a service-based company which makes products.

Our production experts understand variable data, how to arrange that data to create complete label designs and the best order sequence for swift installation progress. Their installations run smoothly, meaning ASG can take an order from the customers desk and return it as a completed project.

This is why ASG Services is considered to be the best and why others imitate. Save your time and money by calling ASG Services on +1 (877) 447-9798. We will be more than happy to speak to you and answer the questions which help you better understand rack labels. Click here for more contact details.

Its estimated that ASG’s installation teams have placed just over one million multi-level rack labels in the past 5 years. Their unrivaled attention to detail, speed and accuracy have created industry benchmarks which we are proud to say, has forced others to improve their offering, bringing a far more professional approach to the industry. We know customers enjoy the benefits, from repeat orders we receive.

Traveling throughout the US, our teams execute some of the largest projects known, against schedules and deadlines agreed early in the project. As one of the final activities to be carried out before a facility goes live, ASG takes its role seriously and communicates progress constantly so the customer can begin maneuvers ahead of time further gaining from their return on investment.

Click here to read more about rack labeling installations.

All products from ASG Services are custom made. We can supply any size, color and content required. Our online store lists stock sizes, for those looking to purchase basic items.

We are not a graphic design studio but we are capable of designing any label layout required. Variable content data and multi field options are possible, our only restriction on the number of barcodes and characters is the size of label you request. We will always suggest a size which best suits your requirements.

Yes, simply because the raw materials we need to create color labels are more expensive, however once an order is over a certain size, the extra cost becomes negligible.

It is true that location labels do not need color to work, but we recommend color to help the users identify key location information quicker. Color is know to improve speed of identification, to read more visit our warehouse color coding article.

Color identification may be used as a level indicator on racking where each level in a rack bay has a unique color, so as the operative looks up, they can distinguish the level quickly and shorten their reading time. It can also be used as a zone identifier particularly with bulk storage floor locations, aisle groups in racking and shelving is another.

Another well represented use of color is with warehouse striping for staging lanes, bulk storage bays and walkways. See our warehouse striping page for more information.

Some customers use it for aesthetics for their in-house branding.

Yes, if we have a sample or measurements and a good image we can copy your label almost exactly.

If you are not able to generate a location file from your warehouse management system, we recommend you use a spreadsheet to help build your own. Spreadsheets allow you to use columns to separate the location sub references, and the rows to quickly expand the number of derivates per run. These columns of data can then be combined to create the barcode data and separately to create the readable elements with separators so operatives can read the rack and shelf location names easily.

Read more on how to build a warehouse location data file.

We're happy to help with any questions, projects, pricing, information or ideas so call today on (877) 447-9798.

Send an email with questions, photos, location files, quantities, sizes, you name it. We'll respond with as much information as you need to take the next step.

Let us know which samples you need and we'll get them on their way with supporting information to help with your decisions.

Pallet Rack Location Labels

Pallet Rack Location Labels

Each barcode location label leaving ASG is different from another, the design, the content, colors, material, and more, combine to make a unique label for a unique pallet location in a unique facility.

Magnetic Rack Labels

Magnetic Rack Labels

The most reusable warehouse tag available is a magnetic rack label. They can be applied at almost any temperature, removed without mess or scraping, be reapplied without peeling and makes your location numbering system as dynamic as the rest of your operation.

Rack Label Cover Up

Rack Label Cover Up

Label cover-up solutions for rack and shelf labels are the most cost-effective method of handling beam revitalization and system update projects.

Take Control of Your Inventory

Take Control of Your Inventory

Do you lose items? Are you unsure exactly what you have and how many are in your warehouse? Its fine to say no, you’re not alone. Warehouses around the world of all sizes, face the constant challenge of maintaining accurate inventory records.

Our online store provides customers with the opportunity to purchase standardized products. The same technology, production and quality control methods are used, so you can be assured of their performance and durability.

Browse now