Warehouse Labels

Warehouse Labels & Identification

Quality and accuracy is a fundamental part of our production processes with millions of labels supplied each year.

Custom Designs, In-House Production and Installed Nationwide

Warehouse Barcode Labels.

ASG Services have been a revered manufacturer and installation specialist in warehouse labels for several decades. Our products are developed to be durable and cost-effective solutions to the logistics and distribution industries.

Our production facility is specifically designed and equipped to handle custom designs, vast quantities and scheduled delivery of warehouse barcode labels. Quality and accuracy is a fundamental part of our production processes. ASG Services operate a multi-phase quality checking system which helps assure accuracy of content, quality of finish and a complete account of the order.

Our label product range is significant. We have designed, adapted and created many of the leading specifications in the field. The importance we place in material selection is critical to durability and cost effectiveness. We firmly believe in supplying the most appropriate label for its use.

Product Range

Warehouse Label Types from ASG Services.

Attention to Detail.

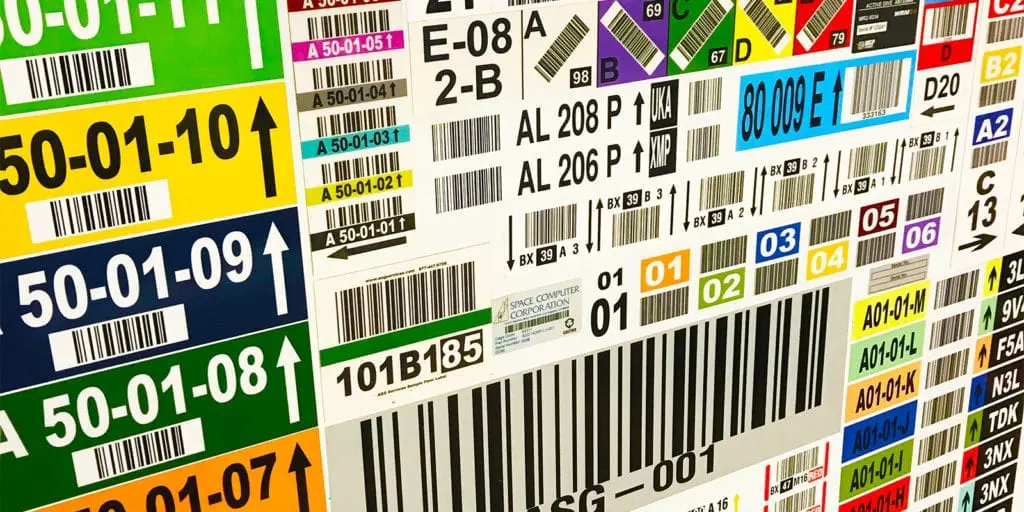

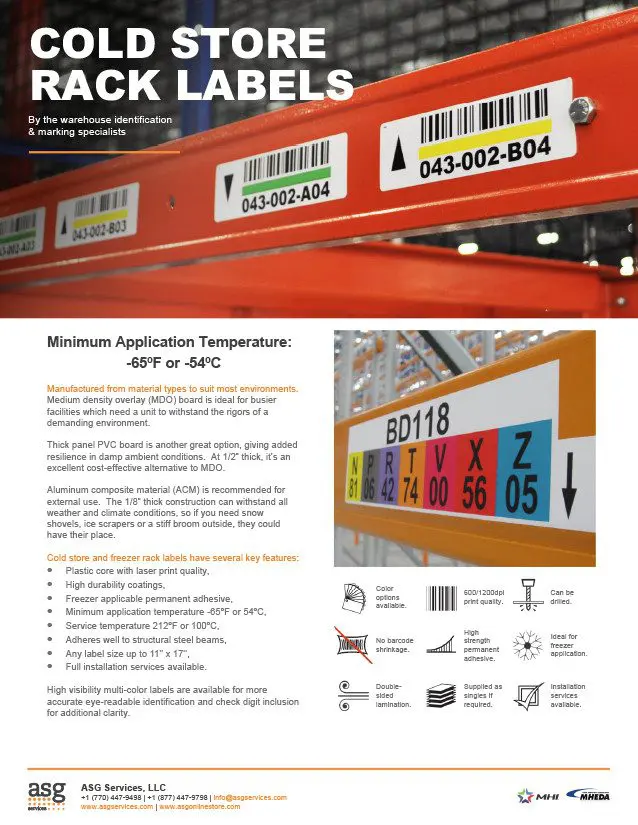

Typical barcode types used by our customers are code 39, code 39 full ASCII and code 128 (with varying subsets). More recently we have been asked to provide data matrix and QR codes thanks to the levels of data these barcodes can present. The label designs produced at ASG can be configured in any conceivable way required. Our software has been developed specifically to offer layout arrangements to suit each specific use.

Something almost unique to us is a diagonal barcode. This helps prevent cross scanning and improves location ID.

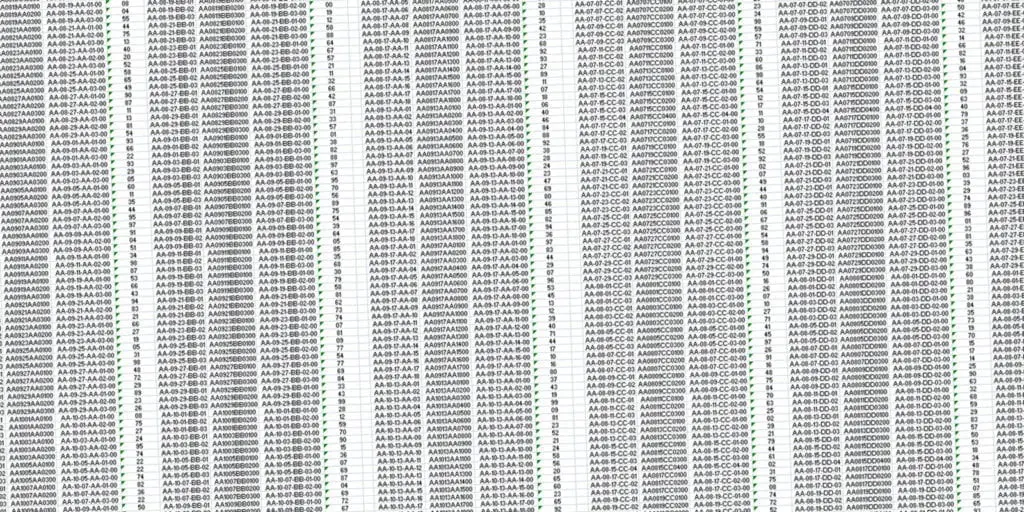

We go the extra mile in helping customers with the complex warehouse label installation projects, read about our storage location data management which is the first productive stage of the sequence.

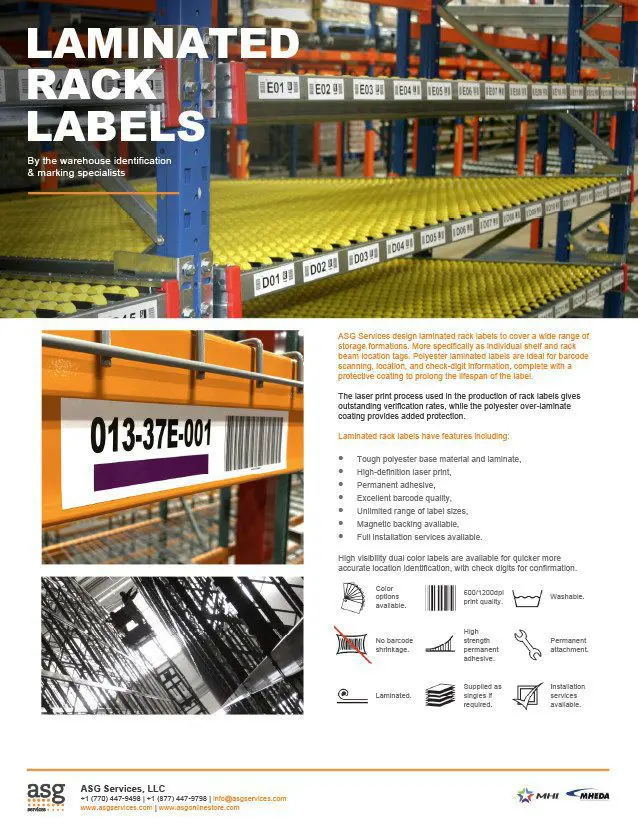

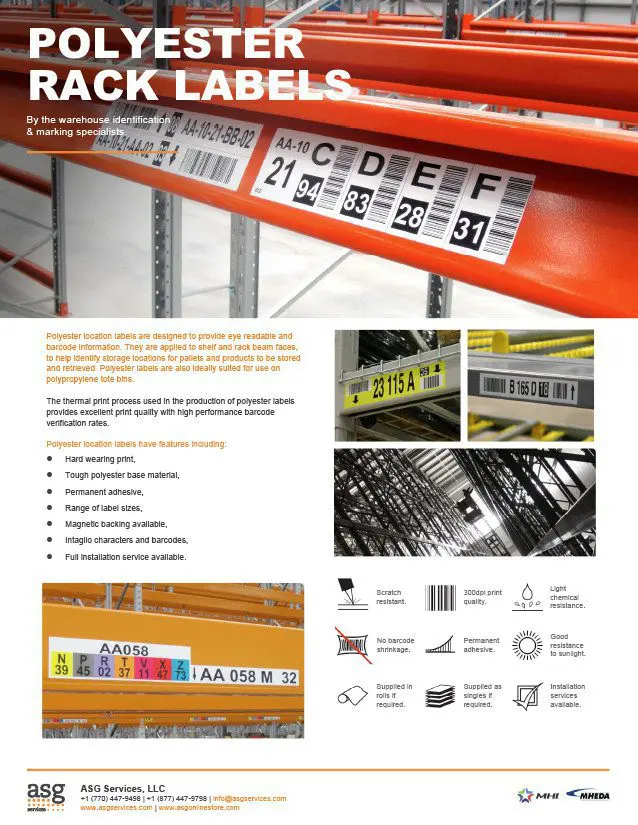

We utilize polyester technologies as primary base material and high-definition digital print systems to create high performing and durable barcode labels. We use other materials such as vinyl, paper stock, and polypropylene, each have unique characteristics and printable variants. Such a difference helps ASG specify accordingly to need, rather than selling overpriced products.

Customization

Design Considerations

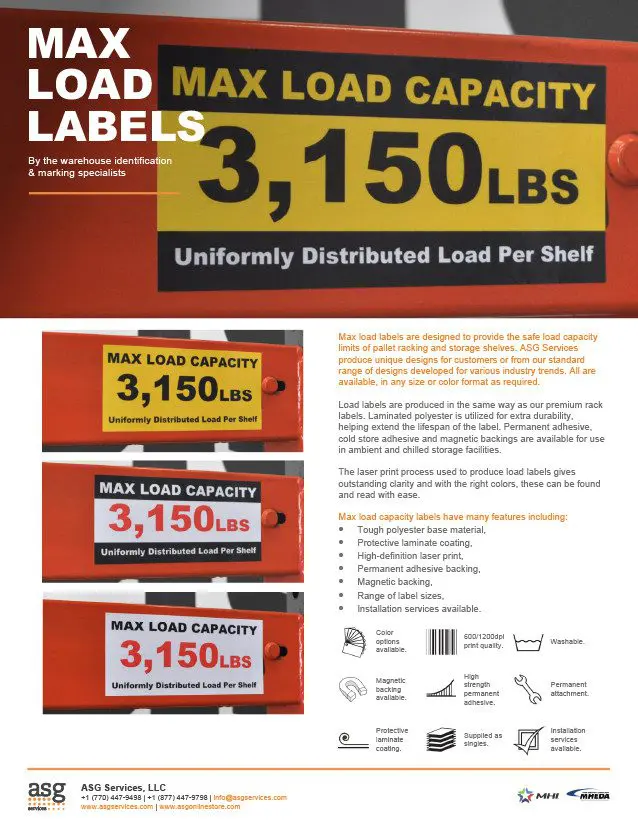

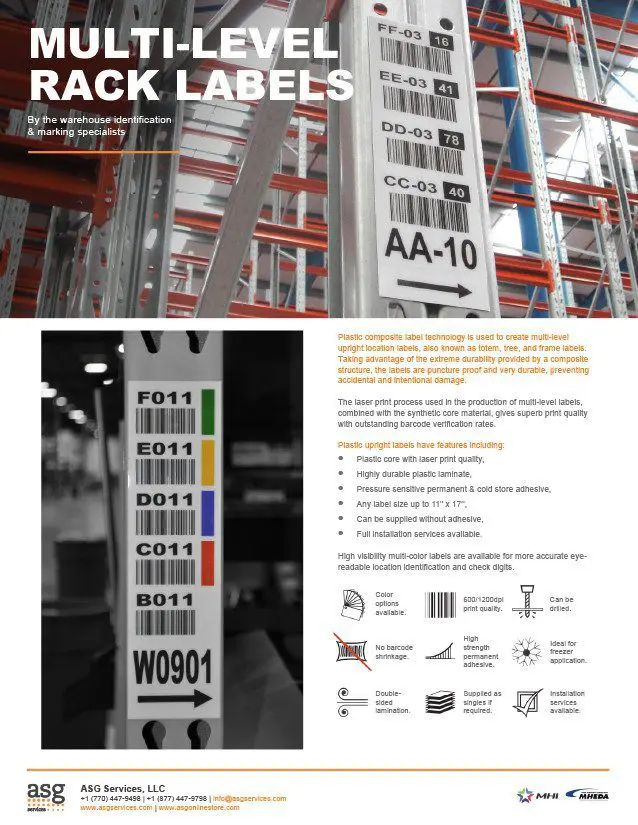

Design and layout formats are important with location id barcodes. The presentation of information can help or hinder the user, particularly when used in fast moving processes, such as small pick modules and high beam rack locations. In contrast, the design of a floor location tag is centered on longevity. The layout must be capable or working even when the tag starts to become dirty.

Our design teams work closely with the customer to give the right solution, and highest performing product they can. Some customers are restricted with size, content and current design obligations, none of which prevent us from providing you with the best possible.

Our project teams are experts in design and planning of labeling projects. They are highly experienced and understand the customers’ needs when designing a system not to mention the operational considerations needed for the installation scheduling. They work closely with every customer to ensure satisfaction and success.

Each customer is a new challenge

Improving Warehouse Identification Solutions.

Services

Warehouse Label Installation Services.

ASG Services’ installation teams travel throughout the US applying durable barcode labels and are fully trained and insured. Their impressive experience is vital when applying location labels within critical time periods.

The attention to detail and understanding of distribution center environments helps them work in and around issues with ease. Their pace and attention to detail is unquestionable helping ASG Services meet customer expectations.

Read more about our warehouse label installations.

Our Client List Keeps Growing!

Resources & Takeaways

Downloads

Help & Advice

Frequently Asked Questions

What sizes do you offer?

Any size you need. Every order we fulfill is customized, so you can specify a size, and we will provide the product as needed.

What designs can you create?

We are not a graphic design studio but we are capable of designing any label layout required. Variable content data and multi field options are possible, our only restriction on the number of barcodes and characters is the size of label you request. We will always suggest a size which best suits your requirements.

Is color more expensive?

We are not a graphic design studio but we are capable of designing any label layout required. Variable content data and multi field options are possible, our only restriction on the number of barcodes and characters is the size of label you request. We will always suggest a size which best suits your requirements.

Why use color?

It is true that location labels do not need color to work, but we recommend color to help the users identify key location information quicker. Color is know to improve speed of identification, to read more visit our warehouse color coding article.

Color identification may be used as a level indicator on racking where each level in a rack bay has a unique color, so as the operative looks up, they can distinguish the level quickly and shorten their reading time. It can also be used as a zone identifier particularly with bulk storage floor locations, aisle groups in racking and shelving is another.

Another well represented use of color is with warehouse striping for staging lanes, bulk storage bays and walkways. See our warehouse striping page for more information.

Some customers use it for aesthetics for their in-house branding.

Which barcode is best?

The barcode you choose to use is dependent on your location or product reference data requirements.

Although we are able to produce almost any barcode type you require, Code 128 is by far the most requested by the storage and logistics industry. This is impart due to the range of characters which can be used (128), being all digits, characters and punctuation and because of its data to size percentage, lots of data can be stored in this narrow width barcode.

Code 39 is the next most popular, which is less useful in terms of characters it can encode, but it is great for its simplicity and ease of scanning capabilities. This is often used with operations handling product specific references and a need to work quickly.

More recently we have been asked for DataMatrix and QR Codes which can contain huge amounts of data compared to linear barcodes.

Can I have check digits?

Yes, these are a common request from our customers looking for pick accuracy improvements.

What are check digits?

They are ‘digits’ to be double ‘checked’ against the warehouse management system (WMS) records. Once the operative has arrived at the pallet or shelf location, they are asked by the system to provide the ‘check-digit’ information which ensures it matches that on the pick sheet or terminal. If their is a match, it is further confirmation they have found the correct location or product and they are able to proceed with the item pick. If it is a failed match, the operative is prevented from completing the pick task, and so knows to look again for the correct storage location.

Check digits are often provided by the warehouse management system, as randomized characters forming an addition to the location code. Most barcodes include a check digit within the symbology, calculated by other characters which form that barcode. In a storage environment, the check digit is typically a separate feature.

Below, you can see the user check digit presented as characters with a black background on a warehouse rack label and a barcode location sign. The operator reads the location reference, scans the barcode and enters the check digit.

My labels will not stick, what can I do?

It depends on several things, the cleanliness of the surface, the surface texture and temperature.

The surface must be free from dust and dirt, oils, cleaning solutions and moisture and any coatings which are loose.

The surface texture is important, for example standard adhesives will not stick to an unfinished wood surface or a galvanized surface where microscopic elements prevent the adhesive working. Additionally, a surface which is very uneven, like a rough plastic mold finish, does not provide enough flat surface area for the adhesive to bond.

Finally, temperature can affect the adhesive. In very cold environments, including chillers and freezers, the elements of the adhesive begin to freeze. Fortunately they do not neutralize, so once warmed they can be used.

I have a design already, can you copy it?

Yes, if we have a sample or measurements and a good image we can copy your label almost exactly.

What do you need to provide me with a quote?

Quantities, sizes, location, aisle widths, beam heights, building operation status, start date and a thorough conversation so we understand exactly what you are hoping to receive from us and to achieve from using a company like ASG Services.

If you install the labels, what assurances can I expect?

- Every label will be in the correct place.

- Labels applied to the rack or shelf in a consistent manor for a uniform presentation.

- If you have missed information from your location references, our teams will report back to ensure they are made and on site before the facility goes live, and hopefully applied before we leave site.

- Barcode and content accuracy.

- Barcode performance and verification guaranteed as an additional service.

Why does label material matter?

Put simply, polyester and polyester composite label material is more durable which prevents barcode distortion during application and shrinkage over time. It also makes it much easier to remove the label, from time to time you may want to re-label your locations due to configuration changes or WMS changes, polyester and poly-composites can be removed without tearing, unlike vinyl materials.

Are laminated warehouse labels worth the extra cost?

If your rack or shelf locations cannot be reconfigured, or the location references are to remain the same for the duration of the facility, then yes lamination is worth having. Lamination adds to the durable nature of our rack labels, it helps protect the print and creates a thicker label which is less susceptible to damage. It does not protect against forklift or pallet impact though!

I want to drive over the labels, will they be ok?

Yes, driving straight over them is fine. Turning on them or scraping pallets across them are the worst things you can do.

How can I stop a label being screwed up on the floor?

Floor labels become screwed up when MHE wheels are turned while on the label. The adhesive and materials are tough, but the twist pressure is extreme. Consider placing them to the side of a storage lane, or placing markers on the floor for drivers to hit before turning their wheels.

Which warehouse label can I use on the floor in a cold store facility?

We produce self adhesive floor labels which are of a durable grade for use on warehouse floors, and we have combined these composite labels with special low temperature adhesive, which work in extremely low temperatures. They are ideal of use in cold store facilities and freezer chambers. We recommend you thoroughly clean the floor surface prior to application and only take the labels into the freezer once you are ready to apply them for maximum performance.

Our high performance freezer adhesive is suitable for application at -20ºF.

Contact us and request samples.

Case Studies

We’ve helped hundreds of global companies

Case studies from some of our amazing customers who are improving their warehouses.

Alternatively, browse our standard range of warehouse labels, crafted with advanced technology for trusted durability.

Find more…

Contact us and discover how we can help.