ASG Services is the leading manufacturer and installation specialist of warehouse signs and identification placards for the logistics and distribution industry.

Our customers range in size and industry. Some customers have below 10,000 sq. Ft warehouses, while others have the enormous 1.5m sq. Ft+ fulfilment centers. We can provide all business types, owing to a wide range of product configurations and our unique data handling expertise, which is critical for high volume location identification.

Manufacturing and project management is located outside Atlanta, GA, with installations carried out throughout the US.

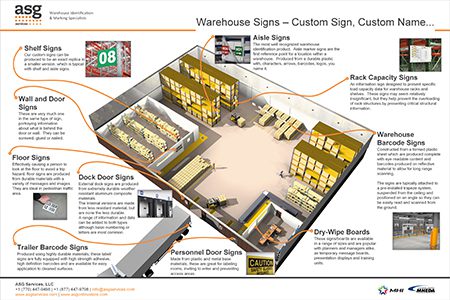

Aisle Signs

Aisle SignsAisle numbering is the most well recognized location identification product, thanks in part to their use in retail environments with aisle content descriptions.

Barcode Hanging Signs

Barcode Hanging SignsBar code signs for bulk storage locations and area numbering are a specialty of ASG Services, with tens of thousands produced each year, in infinite configurations.

5S and Safety Placards

5S and Safety PlacardsCustom designed to meet specific needs within a warehouse facility. Unique messaging, images, layouts, and sizes make them ideal for 5S, 6S and 6 Sigma processes. We offer standard options, but most are as needed by you.

Branded Facility Signs

Branded Facility SignsAll of our warehouse signs can be produced with customer branding included, to improve the professional appearance of your facility, as well as employee morale.

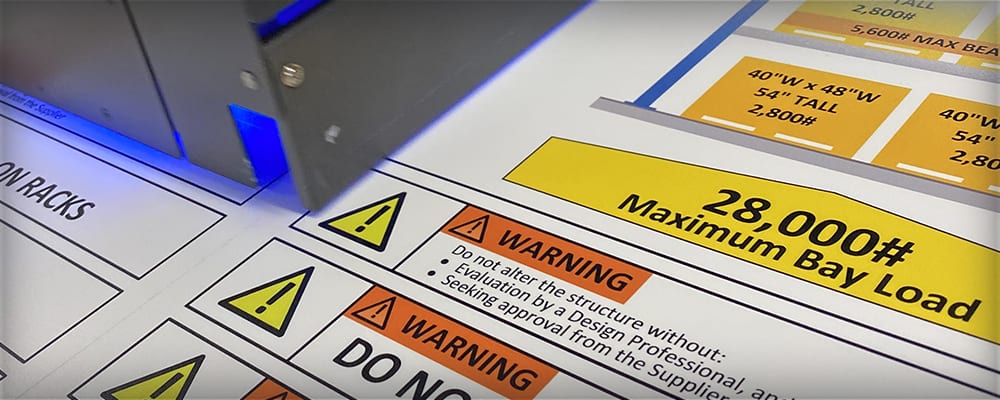

ASG Services is equipped with the latest production equipment and utilizes industry standard materials. We select the best method and materials to suit the environment and design needs of the placard. This helps control costs and maximize durability, both of which we know are important for customers.

The difference between a regular sign shop and what we do is in the handling and production management of variable data content and volume. Speed and methods of production are therefore different and faster, as well is the need for accuracy and sequencing. We are structured to handle logistics and distribution center needs.

High-definition digital systems remove graphical limitations, which is why we have invested in this area. Our production team can create industrial grade functional signs, that carry logos, brand colors and detail which basic sign production technology does not work well with.

Quality control is carefully managed to ensure product quality, content accuracy and sequencing are in order with customer requirements. Failure in these areas can result in significant delays and associated costs during installation, which is something we work tirelessly to avoid.

A variety of materials are used to produce our products including foam board, flute board, aluminum composite, steel, composite woods, and semi-rigid composite structures.

Many signs produced at ASG Services are combinations of materials, for example, retro reflective barcode labels for long range scanning, plastic pouches, clips, and other attachments can be added so the signs are exactly as needed, and often so they can be updated by the customer, for slot naming, part numbers, etc.

Alpha, numeric and/or alphanumeric content is unlimited, color coding, high-definition imagery, 2D and linear barcodes, and even RFID tags can be applied in line with developing technologies.

To help with direction of sight, we can form the signs so the face points toward the people reading them. We select materials for signs like this, so the manipulation is permanent, strong, and durable for warehouse use. Generally, these signs are hanging, or attached perpendicular to the line of sight, and even, so they suggest direction.

Our project department is renowned for quality and ingenuity. We employ project managers who work closely with the customer to establish and finalize product needs, before structuring installation plans and schedules to fit with live operations, or to work within new construction timelines.

Our installation teams are renowned for their experience, attention to detail, and the meticulous approach taken to complete their work in the most efficient way possible. These attributes set them aside from the rest and complete ASG’s turnkey service.

All personnel are trained in-house and insured to work in customer facilities, operational distribution centers and construction sites alike.

We class every sign installation as a project and handle each with the same detail and commitment to success. From simple dock door sign installations, to the 10,000+ warehouse hanging sign systems, both are as important to ASG.

You can read more here about some of our warehouse sign installation projects.

On the larger warehouse barcode sign projects, where completion time makes a huge difference to operation costs, using ASG can and has paid off time and again. You can read about an example here, about ASG Services Rapid Response with Barcode Signs.

We understand that time matters and have made our most popular signs available to buy online.

Choose from a range of standard sizes and layouts to help speed up the order process. We have removed the need to create customer accounts, and the design proof stage, so it is straight to production.

Click the button to see the wide range available.

Yes, we supply all component items so customers can finish the signs themselves. It is rare we are asked but we appreciate that customers like to self-customize.

Warehouse barcode signs are location signs equipped with long-range material used to print the barcode on. The material allows the user to stand around 49ft to 65ft away and scan the barcode with ease, if their hardware is equipped with the relevant components.

All products from ASG Services are custom made. We can supply any size, color and content required. Our online store lists stock sizes, for those looking to purchase basic items.

Most of our installation projects are US based, but we also travel throughout the world with customers who know and trust in our services. We also partner with similar suppliers around the world, so we can often refer you to a company closer to you if needed.

There are many ways, depending on the use, your facility infrastructure and building design as well as sign material allowance. It would be easier to discuss you exact situation with our team, so please feel free to contact us.

Almost any color can be supplied in board and character material. Customers looking to match company brand colors or a previous scheme can be accommodated with a huge range of color options to choose from.

For those looking for more intricate designs or information and diagram signs, colors are unlimited. We utilize digital print technologies for these which are almost limitless.

Order quantities are irrelevant at ASG, we treat all orders as a customized requirement. We do have a minimum order value in dollars, but this is nearly always irrelevant.

Lead times are variable, owing to quantity, complexity and production volumes at the time of order. We prefer to work swiftly with every order since we never know the scale or quantity of the next, so you can be assured that we will not delay the process once your order is placed. We do typically aim for a 1-2 week turnaround from order confirmation.

This is potentially a long answer, however to make things a little more simple… We ask for a list of location references or sign data to be provided, ideally on an excel spreadsheet. In addition, we would ask for any drawings or design ideas you have, based on the quotation you received.

If you change your design idea and need a new quote just ask, it’s better to ask before we start production.

As well as the information to create your signs, we’ll also need payment and/or invoicing details, a delivery address or site address for a warehouse sign installation.

There is always a best fit design, but a best fit for your facility is key to making your operation efficient, but not necessarily the same for another.

We are able to recommend ideas from previous designs, from knowledge and experience in the industry, as well as samples for you to test. Most customers have an idea of what they want or need, if we think there can be improvements or something has been overlooked, we’ll let you know and discuss the details.

Absolutely, we would be happy to do with this with any order.

In short, yes. Our teams are trained in-house and with the relevant external training centers to ensure they know how to do their job and how to do it safely. Any employee who we feel is endangering the safety of others is dealt with swiftly.

Yes, in small and large buildings. We are very experienced in working around other contractors on new builds and carefully plan with the customer and main contractors to achieve a completed installation.

Yes, this is a specialty of ASG Services. Working in and around a fully operational distribution center can be daunting, not to mention it having a significant impact on productivity. Our teams are very experienced in how to work within these facilities and appreciate that the customers work ultimately comes first.

Depending on the scale and access requirements we may be able to working without effecting your operation, or we may need to provide detailed work plans which show how much we can do, where and when. The project team will also detail access requirements and safe working areas to be agreed and confirmed with the customer.

There are several things to consider with the height of signs, they are:

● Sprinkler interference –

Signs should always be placed at sufficient distance from sprinkler heads to ensure the diffusion is not altered or prevented by the signs or rails. If hanging the signs above, this is not an issue.

● Block stack storage height –

The signs will need to be higher than the highest stacking point, but you should consider here that if the signs are hanging behind the front edge of the stack, they will need to be higher still, due to the angle of sight.

● Scanner distance capabilities –

Most modern scanners are equipped with long range scanning components, however this should be checked with the manufacture/supplier. If you want to test the distance before ordering, you might consider requesting a sample to perform on site tests.

● Sign/barcode size –

In a simple explanation, the wider a barcode is, the greater the distance it can be scanned at. Having a wider barcode will need a bigger sign, resulting in a more expensive product.

Yes, we operate an archive system so your previous orders including designs, location references and other documentation will be available for retrieval.

Yes, we can retrieve information from our archive and apply this to your new location references, effectively replicating your previous warehouse identification system.

Call us on +1 (877) 447-9798 to speak with us about your situation and get the answers to help with your project.

Send your email with as much information, images, drawings and any other items as you can to help us respond with the best reply possible.

We provide standard versions of our range which you can buy online, visit our online store for more.

Our online store provides customers with the opportunity to purchase standardized products. The same technology, production and quality control methods are used, so you can be assured of their performance and durability.

Browse now